Poly-Flo

Co-extruded Double Containment

Higher safety factor from our market exclusive unitary extrusion process than any other fabricated double contained product on the market.

Integrated double containment helps meet EPA requirements for transportation of hazardous chemicals.

Standardized dimensions eliminate the need for special welding clamps. Poly-Flo can now be welded with standard Asahi butt welding equipment.

Ideally suited for underground applications such as direct burial or directional drilling.

Technical Specification

World Class Resin

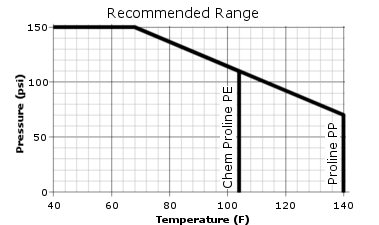

Polyethylene Poly-Flo utilizes Chem Proline advanced PE resin which is ideally suited for the most demanding applications. Chem Proline resin has proven success in applications for potable water to high concentration sodium hypochlorite.

Polypropylene Poly-Flo is manufactured from Proline PP-R resin which pioneered the market more than 25 years ago for polypropylene pipe and fittings. The Proline PP-R resin continues to evolve to ensure cutting edge solutions are always available.

Standard Components

Fabricated & Machined

Pipe is available in standard 5m (16.4 foot) lengths at Asahi in Lawrence, Massachusetts. It can be special ordered in lengths up to 11.8m (38 feet) or coiled up to 3,000 feet.

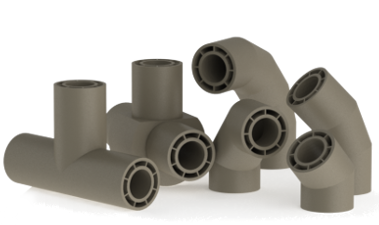

Our standard fitting offering includes fabricated and machined full pressure rated fittings as well as fabricated lower pressure drainage pattern fittings.

Specialty Components

Dogbones & Flanges

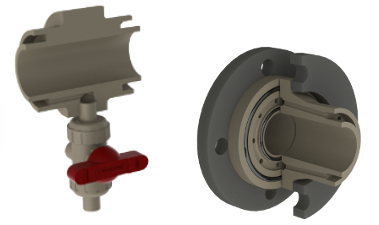

At the core of our all Asahi Double Containment Systems are specialty components which solve specific tasks, such as leak detection, sampling or compartmentalization.

Poly-Flo specialty components include several configurations of our patented Dogbone, restraint fittings and stub ends.

Each fitting is available in flow through as well as solid options allowing customers to design their systems as efficiently and uniquely as they want.